Grasping the Needlework Digitizing Refine: Your Ultimate Guide

Needlework digitizing is a thorough craft that requires precision and experience to translate elaborate styles right into electronic layouts for device needlework. As craftsmens embark on this journey to understand the needlework digitizing procedure, an extensive understanding of the fundamentals establishes the structure for excellence.

Recognizing Needlework Digitizing Basics

Needlework digitizing essentials create the foundation upon which intricate styles are equated right into machine-readable layouts for specific sewing. This first action in the needlework digitizing procedure is crucial for guaranteeing that the final embroidered product is a devoted representation of the original style. Recognizing needlework digitizing essentials entails grasping key concepts such as stitch kinds, sew instructions, thickness, padding, and draw payment.

Sew kinds play a crucial function in figuring out the aesthetic and textural result of the embroidered design. By picking the suitable stitch kind, whether it be satin, fill, or running stitch, digitizers can attain the wanted result and boost the total top quality of the needlework. In addition, stitch instructions affects the circulation and measurement of the design, while density determines the spacing and insurance coverage of the stitches.

In addition, rug stitching offers security to the layout by protecting the fabric and protecting against distortion during the embroidery procedure. Draw payment is another crucial consideration to counteract the natural propensity of material to agreement when stitched. Understanding these embroidery digitizing essentials is fundamental for developing professional-quality embroidered items.

Choosing the Right Digitizing Software Application

Picking the appropriate digitizing software application is a crucial decision that dramatically impacts the effectiveness and top quality of the embroidery digitizing process. Digitizing for Embroidery. When selecting the appropriate digitizing software, it is important to take into consideration factors such as the complexity of styles you plan to create, the user-friendliness of the software application, the degree of consumer assistance offered, and the compatibility with your embroidery device

There are different digitizing software application alternatives readily available in the market, ranging from fundamental programs for novices to innovative software program for professional digitizers. Some popular choices include Wilcom EmbroideryStudio, Hatch Needlework Software Program, and PulseID. These software supply a wide variety of tools and attributes to aid you develop detailed layouts effortlessly.

Before choosing, it is advisable to explore the different software program alternatives via cost-free tests or trials to establish which one ideal matches your demands. In addition, checking out evaluations and seeking recommendations from skilled digitizers can offer important insights into the staminas and weaknesses of each software bundle (Digitizing for Embroidery). By very carefully evaluating your requirements and comparing the attributes of various digitizing software application, you can make an informed choice that enhances your needlework digitizing process

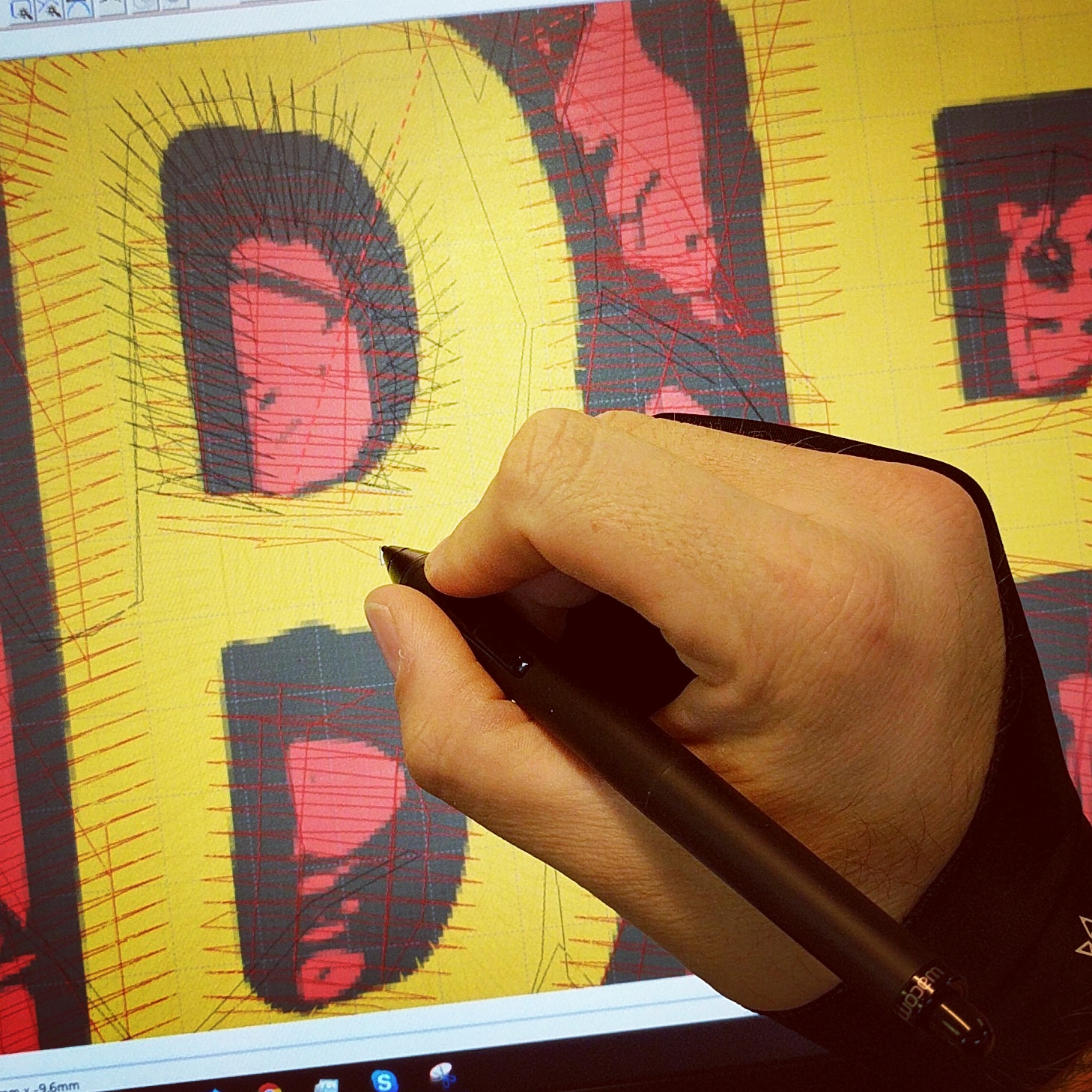

Digitizing Tools and Techniques

Optimizing Layout Settings for Embroidery

Grasping the ins and outs of design settings is basic in achieving optimum lead to the needlework digitizing procedure, building upon the structure laid by understanding digitizing tools and techniques. When optimizing layout setups for embroidery, it is vital to think about aspects such as stitch type, density, padding, draw payment, and registration. Stitch kind choice affects the overall look and feeling of the layout, with alternatives like satin, fill, and running stitches using different textures and effects. Thickness describes the spacing and thickness of stitches, affecting the design's insurance coverage and durability. Correct padding sewing offers stability and protects against textile distortion, click for more info particularly for complex layouts or on elastic materials. Draw payment adjusts for textile stretch during stitching, ensuring exact layout replication. Enrollment setups align various aspects of the layout properly, preserving overall layout stability. By fine-tuning these layout settings, embroiderers can enhance the high quality and precision of their stitched creations.

Troubleshooting Common Digitizing Issues

When encountering typical digitizing issues during the needlework process, it is vital anonymous to comprehend the origin triggers and implement efficient remedies quickly. One common issue is stitch thickness problems, where stitches might be too thick, causing the textile to pucker, or also sporadic, leading to voids in the design. Readjusting the stitch density setups in the digitizing software program can help solve this issue.

One more frequent difficulty is string breaks during the needlework process. This can happen as a result of different factors such as inaccurate stress settings, boring needles, or making use of low-quality string. Guaranteeing correct maintenance of the embroidery equipment, including regular needle modifications and tension modifications, can lessen the occurrence of thread breaks.

In addition, style enrollment errors can lead to misaligned aspects within the needlework design. Examining the design positioning in the digitizing software program and making required changes before sewing can help in preventing this issue. By dealing with these common digitizing issues quickly and effectively, you can guarantee a smoother embroidery process and premium completed products.

Final Thought

To conclude, mastering Related Site the embroidery digitizing process requires a solid understanding of the basics, the right choice of software, and knowledge of tools and techniques. Optimizing style settings and troubleshooting common digitizing issues are crucial action in making certain high-grade needlework outcomes. By following these actions diligently, one can attain accuracy and effectiveness in the digitizing process.